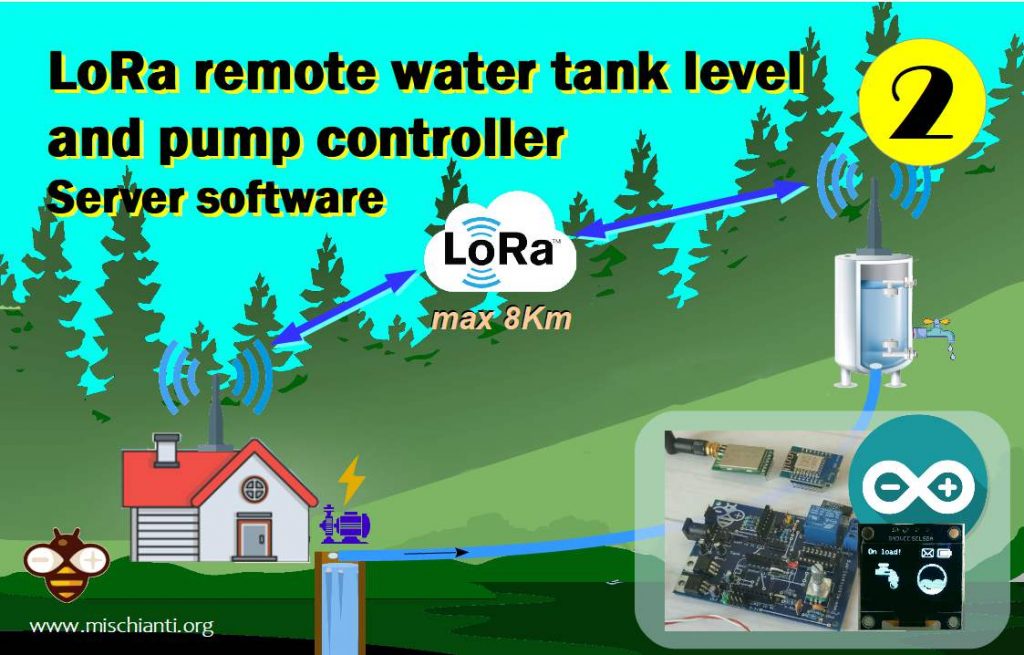

LoRa remote water level and pump controller (esp8266): server software – 2

Now we are going to examine the functional logic of the devices.

The Server has the command of the situation, and It must control the pump with a relay and expect the status from the client. For the safety system, we insert an hour limit of the active pump if some problems occur, or you can use a ping mode that expects a keep-alive message every 10 seconds if there is no message in that period.

EByte E32 configuration

The LoRa device is an E32, and It’s configured for a fixed transmission with a high wake-up time to send a big preamble to ensure the client It’s waked.

Refer to the article “Ebyte LoRa E32 device for Arduino, esp32 or esp8266: configuration“.

ResponseStructContainer c;

c = e32ttl.getConfiguration();

Configuration configuration = *(Configuration*) c.data;

configuration.ADDL = SERVER_ADDL;

configuration.ADDH = SERVER_ADDH;

configuration.CHAN = SERVER_CHANNEL;

configuration.OPTION.fixedTransmission = FT_FIXED_TRANSMISSION;

configuration.OPTION.wirelessWakeupTime = WAKE_UP_2000;

configuration.OPTION.fec = FEC_1_ON;

configuration.OPTION.ioDriveMode = IO_D_MODE_PUSH_PULLS_PULL_UPS;

configuration.OPTION.transmissionPower = POWER_20;

configuration.SPED.airDataRate = AIR_DATA_RATE_010_24;

configuration.SPED.uartBaudRate = UART_BPS_9600;

configuration.SPED.uartParity = MODE_00_8N1;

ResponseStatus rs = e32ttl.setConfiguration(configuration, WRITE_CFG_PWR_DWN_SAVE);

SERIAL_DEBUG.println(rs.getResponseDescription());

Buttons and relay

Menu and actions are managed by a pcf8574 and an encoder, and I explain better the wiring and the software in my tutorial “PCF8574 i2c digital I/O expander: Arduino, esp8266 and esp32, rotary encoder“.

But you must pay attention to managing interruptions on the shared i2c channel. In this case, I must disable and re-enable the pcf8574 interrupt when refreshing the i2c display, and you must check the relative article on ssd1306.

pcf8574.detachInterrupt();

if (changedButton) {

currentScreen = clickMenu(currentScreen, encoderValue);

changedButton = false;

}

renderScreen(currentScreen);

display.clearDisplay();

pcf8574.attachInterrupt();

The relay is managed by a single pin and live synchronized.

void startPump(){

DEBUG_PRINTER.println("START PUMP");

pumpIsActive = true;

digitalWrite(RELAY_PIN, HIGH);

pumpStartTime = millis();

lastMillisMessageReceived = millis();

}

void stopPump(){

DEBUG_PRINTER.println("STOP PUMP");

pumpIsActive = false;

digitalWrite(RELAY_PIN, LOW);

pumpStopTime = millis();

}

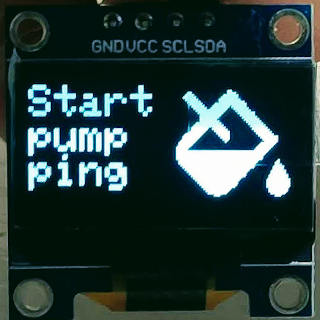

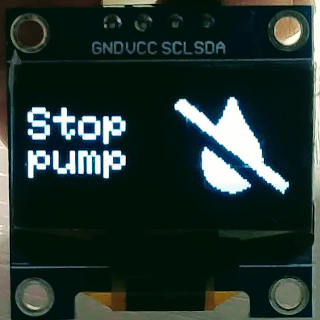

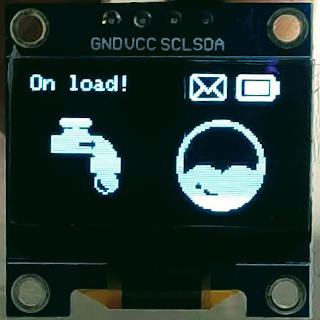

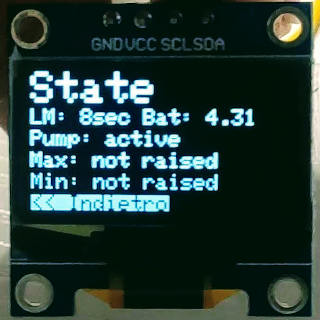

Display menu

I use an Oled ssd1306 display, very little, the complete animations guide and icon generation here “SSD1306 OLED Display: draw images, splash, and animations“.

I’m going to manage a set of Icons to understand the operation better. I change the menu icon by rotating an encoder and selecting it by clicking the encoder.

I manage the multilingual including a file with all the labels

#include "include/ita.h"

//#include "include/eng.h"

I use a simple state machine to manage the Display; a switch managed by the encoder value is used to show the correct icon; the values are:

PUMP_START_MENU: start the pump and wait for it to be full; the only additional security is a timer that stops the pump after one hour.

PUMP_START_PING_MENU: start the pump and wait for a ping message every 20 seconds; if the tank is full or there is no message after 20 seconds, It stops the pump.

PUMP_STOP_MENU: stop the pump and tell the client to go into sleep mode.

STATUS_MENU: graphical status of the devices (pump active, battery status, and tank level).

STATUS_MENU_DETAILED: descriptive status of the devices.

void mainMenu(String title = SCREEN_MAIN_TITLE) {

display.clearDisplay(); //for Clearing the display

switch (encoderValue) {

case PUMP_START_MENU:

displayIconLabel(START_PUMP_LABEL, 2);

display.drawBitmap(70, 5, tapDrop, 54, 54, WHITE); // display.drawBitmap(x position, y position, bitmap data, bitmap width, bitmap height, color)

break;

case PUMP_START_PING_MENU:

displayIconLabel(START_PUMP_PING_LABEL, 3);

display.drawBitmap(70, 5, containerDrop, 54, 54, WHITE); // display.drawBitmap(x position, y position, bitmap data, bitmap width, bitmap height, color)

break;

case PUMP_STOP_MENU:

displayIconLabel(STOP_PUMP_MENU_LABEL, 2);

display.drawBitmap(70, 5, dropSlash, 54, 54, WHITE); // display.drawBitmap(x position, y position, bitmap data, bitmap width, bitmap height, color)

break;

case STATUS_MENU:

displayIconLabel(STATUS_DEVICE_MENU_LABEL, 1);

display.drawBitmap(70, 5, info, 54, 54, WHITE); // display.drawBitmap(x position, y position, bitmap data, bitmap width, bitmap height, color)

break;

case STATUS_MENU_DETAILED:

displayIconLabel(STATUS_DETT_MENU_LABEL, 1);

display.drawBitmap(70, 5, info, 54, 54, WHITE); // display.drawBitmap(x position, y position, bitmap data, bitmap width, bitmap height, color)

break;

default:

break;

}

display.display();

}

The click action is managed by a function that uses the current screen and the encoder value to the correct screen.

SCREEN clickMenu(SCREEN screen, int state){

SCREEN returningScreen = SCREEN_ERROR;

switch (screen) {

case SCREEN_MAIN:

returningScreen = mainMenuState((MENU_MAIN_STATE)state);

break;

case SCREEN_STATUS_DEVICE:

case SCREEN_STATUS_DEVICE_DETAILED:

case SCREEN_ERROR:

returningScreen = checkMenuState();

break;

default:

break;

}

encoderValue = 0;

screenEncoderSizeMax = screenEncoderSize[returningScreen];

SERIAL_DEBUG.print(F("CLICK --> "));

SERIAL_DEBUG.print( F("FROM SCREEN --> ") );

SERIAL_DEBUG.print( screen );

SERIAL_DEBUG.print(F(" - TO SCREEN --> "));

SERIAL_DEBUG.print( returningScreen );

SERIAL_DEBUG.print(F(" - MENU STATE --> "));

SERIAL_DEBUG.println( state );

return returningScreen;

}

Then, a function renders the correct screen based on the screen selected:

void renderScreen(SCREEN screen){

switch (screen) {

case SCREEN_MAIN:

mainMenu();

break;

case SCREEN_STATUS_DEVICE:

checkPage();

break;

case SCREEN_STATUS_DEVICE_DETAILED:

checkPageDetailed();

break;

case SCREEN_ERROR:

errorPage();

break;

default:

break;

}

}

Actions

When a state is selected (clicked), the correct operation is processed by the relative state management, and the return SCREEN shows the executed action.

SCREEN clickMenu(SCREEN screen, int state){

SCREEN returningScreen = SCREEN_ERROR;

switch (screen) {

case SCREEN_MAIN:

returningScreen = mainMenuState((MENU_MAIN_STATE)state);

break;

case SCREEN_STATUS_DEVICE:

case SCREEN_STATUS_DEVICE_DETAILED:

case SCREEN_ERROR:

returningScreen = checkMenuState();

break;

default:

break;

}

encoderValue = 0;

screenEncoderSizeMax = screenEncoderSize[returningScreen];

SERIAL_DEBUG.print(F("CLICK --> "));

SERIAL_DEBUG.print( F("FROM SCREEN --> ") );

SERIAL_DEBUG.print( screen );

SERIAL_DEBUG.print(F(" - TO SCREEN --> "));

SERIAL_DEBUG.print( returningScreen );

SERIAL_DEBUG.print(F(" - MENU STATE --> "));

SERIAL_DEBUG.println( state );

return returningScreen;

}

Here are the click actions for the main screen

SCREEN mainMenuState(MENU_MAIN_STATE state){

SERIAL_DEBUG.print(F("mainMenuState --> "));

SERIAL_DEBUG.println(state);

ResponseStatus rs;

switch (state) {

case PUMP_START_MENU:

DEBUG_PRINTLN("PUMP_START_MENU");

stopPump();

operationalSelected = OPERATION_NORMAL;

SERIAL_DEBUG.println("OPERATION_NORMAL");

rs = sendPumpMessageToClient("start", true);

if (rs.code!=SUCCESS) {

errorMessage = rs.getResponseDescription();

return SCREEN_ERROR;

}

actionSelected = ACTION_AUTO;

return SCREEN_STATUS_DEVICE;

break;

case PUMP_START_PING_MENU:

DEBUG_PRINTLN("PUMP_START_PING_MENU");

stopPump();

operationalSelected = OPERATION_PING;

SERIAL_DEBUG.println("OPERATION_PING");

rs = sendPumpMessageToClient("start", true);

if (rs.code!=SUCCESS) {

errorMessage = rs.getResponseDescription();

return SCREEN_ERROR;

}

actionSelected = ACTION_AUTO;

return SCREEN_STATUS_DEVICE;

break;

case PUMP_STOP_MENU:

DEBUG_PRINTLN("PUMP_STOP_MENU");

stopPump();

actionSelected = ACTION_STOP;

operationalSelected = OPERATION_DISABLED;

rs = sendPumpMessageToClient("stopp", true);

if (rs.code!=SUCCESS) {

errorMessage = rs.getResponseDescription();

return SCREEN_ERROR;

}else{

return SCREEN_STATUS_DEVICE;

}

break;

case STATUS_MENU:

return SCREEN_STATUS_DEVICE;

break;

case STATUS_MENU_DETAILED:

return SCREEN_STATUS_DEVICE_DETAILED;

break;

default:

break;

}

return SCREEN_ERROR;

};

The function manages the messages sendPumpMessageToClient

ResponseStatus sendPumpMessageToClient(String action, bool wakeUp){

ResponseStatus rsW;

if (wakeUp){

rsW = setWakeUpMode();

}else{

rsW = setNormalMode();

}

SERIAL_DEBUG.println(rsW.getResponseDescription());

if (rsW.code != SUCCESS) return rsW;

JsonObject root = doc.to<JsonObject>();

root["type"] = action;

root["mode"] = (int)operationalSelected;

int size = measureJson(doc)+1;

char buf[size];

serializeJson(doc, buf, size);

SERIAL_DEBUG.println(buf);

SERIAL_DEBUG.println(measureJson(doc));

SERIAL_DEBUG.print("Send message to client ");

SERIAL_DEBUG.print(CLIENT_ADDH, DEC);

SERIAL_DEBUG.print(" ");

SERIAL_DEBUG.print(CLIENT_ADDL, DEC);

SERIAL_DEBUG.print(" ");

SERIAL_DEBUG.print(CLIENT_CHANNEL, HEX);

SERIAL_DEBUG.println(" ");

SERIAL_DEBUG.println("Mode --> ");

SERIAL_DEBUG.println(e32ttl.getMode());

rsW = e32ttl.sendFixedMessage(CLIENT_ADDH, CLIENT_ADDL, CLIENT_CHANNEL, buf, size);

SERIAL_DEBUG.println(rsW.getResponseDescription());

if (rsW.code != SUCCESS) return rsW;

rsW = setReceiveMode();

return rsW;

}

Thanks

You can find the complete master code on my GitHub as usual.

- LoRa remote water tank level and pump controller: intro

- LoRa remote water level and pump controller: server software

- LoRa remote water level and pump controller: client software

- LoRa remote water level and pump controller: server PCB

- LoRa remote water level and pump controller: client PCB

- LoRa remote water level and pump controller: assemble server and 3D printed case

- LoRa remote water level and pump controller: assemble client and 3D printed case