CNC Cyclone PCB Factory: settings and tests – Part 7

Firmware: Upload

For the firmware I use a grbl from here.

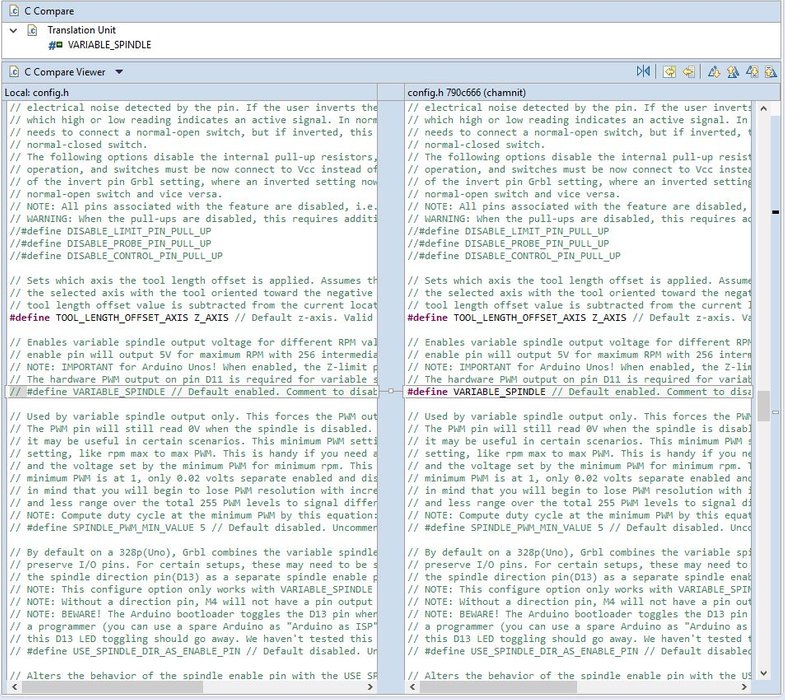

In my particular situation I don’t use a variable splindle so I made a fork of the project hereready to be uploaded as normal ino scketch program (If you want you can import it as sloeber project also).

Firmware: Configuration

$0=10 (step pulse, usec)

$1=25 (step idle delay, msec)

$2=0 (step port invert mask:00000000)

$3=3 (dir port invert mask:00000110)

$3 Identify the direction of movement, you can obtain the same inversion with rotation of stepper plug.

$4=0 (step enable invert, bool)

$5=0 (limit pins invert, bool)

$6=0 (probe pin invert, bool)

$6 Identify the direction when you do the probe

$10=1 (status report mask:00000011)

$11=0.010 (junction deviation, mm)

$12=0.002 (arc tolerance, mm)

$13=0 (report inches, bool)

Here you can find adjustment of movement.

$20=1 (soft limits, bool)

$21=1 (hard limits, bool)

$22=1 (homing cycle, bool)

This is the property for Limits and homing activation you must activate (and test) in this manner:

activate $21 (hard limits, anche check if they works correctly, click by hand the limit switch when machine is in idle state);

then activate $22 first and $20 then, $22 is the activation of homing and $20 is soft limit (check the size defined in the $130, $131, $132, i explain in order), if you activate $20 first you can broke configuration.

$23=3 (homing dir invert mask:00000001)

Here the direction of homing It’s dependent on $3 configuration, if you change $3 you must correct this.

$24=25.000 (homing feed, mm/min)

$25=500.000 (homing seek, mm/min)

Here the speed of homing, for my stepper is to high and block the movement.

$26=250 (homing debounce, msec)

$27=1.000 (homing pull-off, mm)

Other homing adjustment.

$30=1000 (Max spindle speed, RPM)

$31=0 (Min spindle speed, RPM)

$32=0 (Laser mode, boolean)

$30 and $31 are needed if you use PWM and variable speed, but I used a Relay to activate spindle.

$32 is laser mode new configuration for laser CNC.

$100=159.000 (x, step/mm)

$101=159.000 (y, step/mm)

$102=199.000 (z, step/mm)

Here there are the number of step to do 1mm of movement, very important for precision, normally this value is ok for all Nema17 motor but exists not only 200 step motor but 400 or 75 step motor.

I create a simple program to get this value, you can find here.

$110=300.000 (x max rate, mm/min)

$111=300.000 (y max rate, mm/min)

$112=150.000 (z max rate, mm/min)

This is the max speed of your CNC, remember that threaded rod is a big demultiplex so the speed that you can raise isn’t very high.

$120=10.000 (x accel, mm/sec^2)

$121=10.000 (y accel, mm/sec^2)

$122=10.000 (z accel, mm/sec^2)

Acceleration parameter, we use a big demultiplex as described so they aren’t very important for now.

$130=160.000 (x max travel, mm)

$131=96.000 (y max travel, mm)

$132=40.000 (z max travel, mm)

Here there is the size of CNC area.

Test: Homing

Now start the homing test, I create a simple video, I use Universal Gcode Sender, but there are a lot of alternatives like bCNC, Mach3 ecc..

Test: Probe

Simple video of Probe testing.

Test: Autolevelling ChiliPeppr

Autolevelling feature not working on UGS so to test this features I use ChiliPeppr.

Test: Autolevelling bCNC

My first choice is bCNC now.

Test: First File Sended

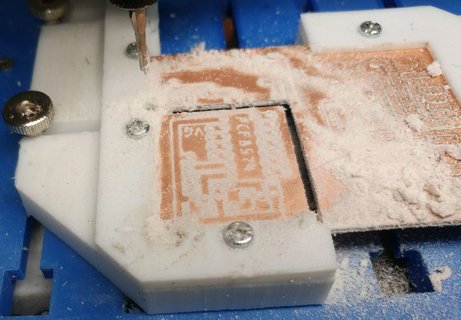

Test: First Milling PCB With Noise Problem.. and Panic!!

I try to mill a PCB without a service board to reduce noise and in the video you can see what’s happend.

Go to the first minute of video (1:06).

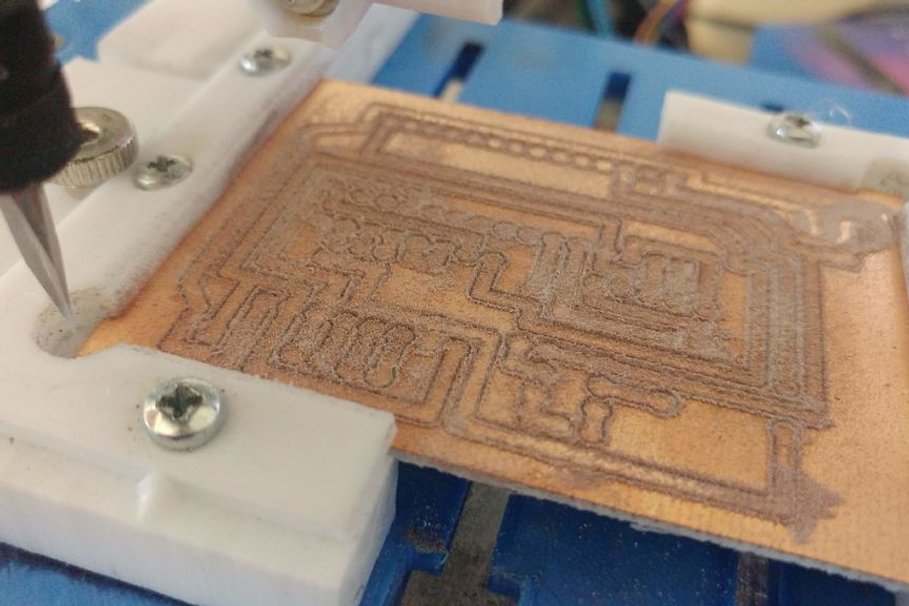

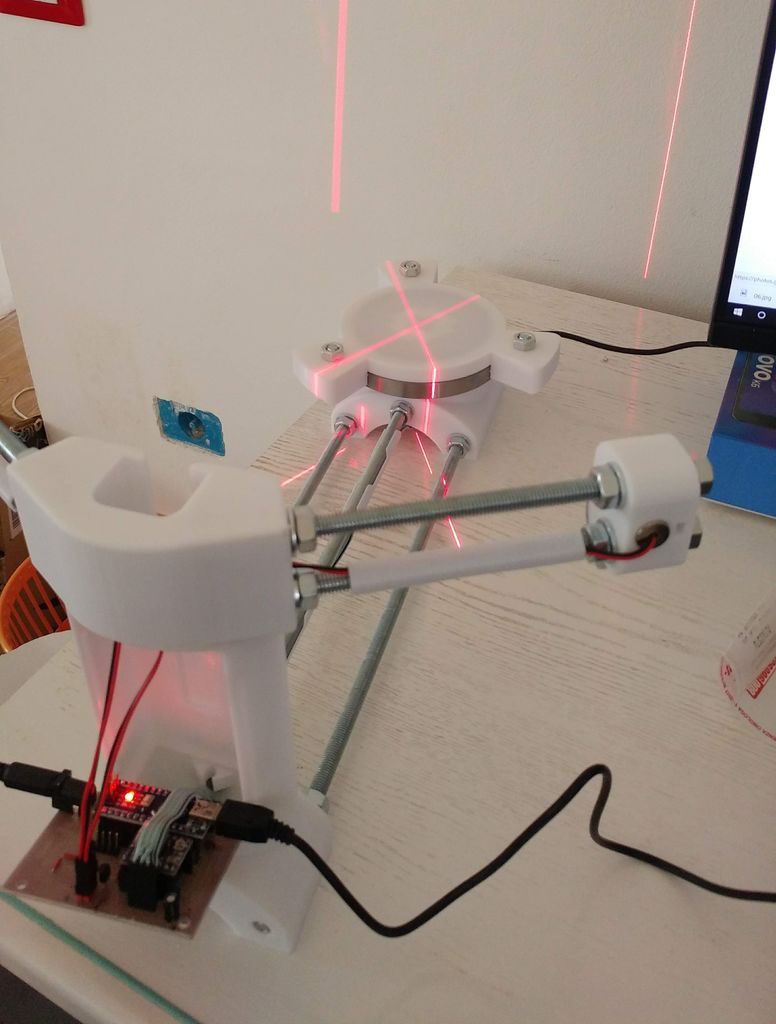

Test: Milling PCB (Puff!!)

First I need a vacuum cleaner 😛

Here you can see Cyclone PCB at work.

Now work very good, and It’s very precise.

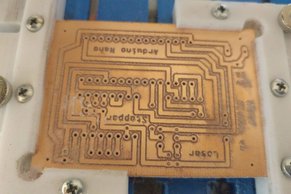

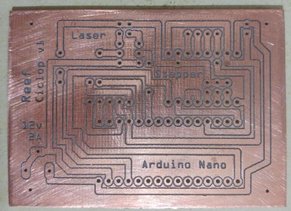

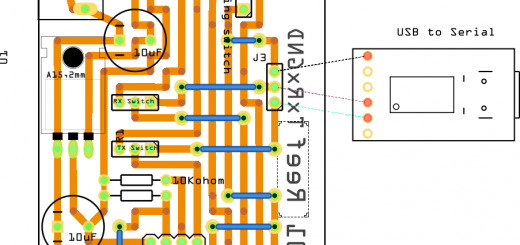

Test: Second Milling PCB, My Ciclop 3D Scanner Board

Thanks

As already said (with your contribution) I would like to create a board that includes all the fixes, if you have any experiences to share, write me or comment, so I can integrate your improvements.

Recap of all link

Original project: https://github.com/CarlosGS/Cyclone-PCB-Factory

Where you can find a lot of usefully info and shopping list.

My design https://mischianti.org/category/3d-printer/

Where you can find fixed part and upgrade.

Grbl github: https://github.com/gnea/grbl

Where you can find arduino grbl firmware.

My github: https://github.com/xreef

Where you can find ready to upload grbl and a program to calculate step/mm, or service board schema.

Bluetooth information: https://mischianti.org/arduino-remote-wireless-programming/

How to program and wire bluetooth.

Guide to milling PCB with ruoter: https://mischianti.org/category/tutorial/milling-pcb-tutorial/

Some video: https://www.youtube.com/playlist?list=PLOHujNnRvJ6…

Articles

- CNC Cyclone PCB Factory: mechanics

- CNC Cyclone PCB Factory: CNC Shield, stepper and driver

- CNC Cyclone PCB Factory: limit switch

- CNC Cyclone PCB Factory: probe and relay

- CNC Cyclone PCB Factory: control panel and bluetooth

- CNC Cyclone PCB Factory: boards schema and other

- CNC Cyclone PCB Factory: settings and tests